Reverse osmosis plant (RO Plant)

A reverse osmosis plant is a manufacturing plant which has the process of reverse osmosis process takes place. Modern reverse osmosis plant needs six kilowatt-hours of electricity to purify one cubic meter of water. The process which results in salty briny waste in a considerable amount. The main challenge for RO plants is to find the suitable ways to reduce energy consumption, use ecological energy sources, and improve the process of purification and to renovate in the area of waste management to deal with the waste. Self-contained water treatment plants using the process of reverse osmosis, generally called reverse osmosis water purification units.

Reverse osmosis is a process that any industry uses to clean water, whether for industrial process applications or to convert briny water, to clean up wastewater and to recover its salts from industrial processes.

Reverse osmosis cannot be removing all contaminants from water as dissolved gases -dissolved carbon dioxide, oxygen and not being removed. But reverse osmosis is very effective at removing some other products such as trihalomethanes , solvents, some pesticides and other volatile organic compounds.

Reverse osmosis process: -In the reverse osmosis process cellophane or semipermeable like membranes separate purified water from adulterated water. RO is when a pressure is applied to the concentrated side of the semipermeable membrane forcing the purified water into the diluted side, the rejected impurities or contaminants from the concentrated side being washed away in the reject water. RO can also work as an ultra-filter removing particles such as micro-organisms that may be too large to pass through the pores or small holes of the membrane.

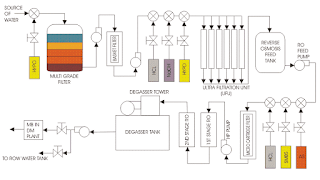

The different stages of operation in RO plant shown in figures.

.png)

No comments:

Post a Comment