Techshore School of NDT Centre is an initiative of the leading professional & reputed training brand of Techshore Inspection Services, which is having training centres all over Kerala. Techshore offers courses in NDT Level II from early 2015 and successful in providing placements for all those candidates in reputed companies with attractive salary packages and perks.

Pulsed Eddy Current Testing

Introduction

Pulse eddy current testing is a method which is used to semi-quantify the wall thickness of steel hidden behind insulations. The main strength of PECT is its ability to inspect carbon steel through insulation commonly covering pipes and vessels. Its main limitations are that PECT measures steel thickness average over a large area of the test specimen called the "Footprint".This implies PECT can detect general wall loss but not localized corrosion.

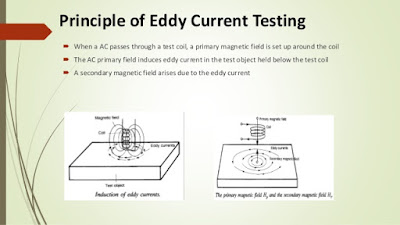

Basic Working Principle

The device consists of a probe which is connected to a pulse generator and computerized data acquisition System. The probe houses transmitter coils to generate a powerful magnetic pulse, which penetrates nonmagnetic materials between the coil and the object. The change in the magnetic field at both the leading and trailing edge of the pulse induces eddy currents in the material. When applying PECT to ferromagnetic steel, such as carbon and low -alloy steels, the eddy currents will be concentrated on the surface of the test specimen. Subsequently, the eddy currents will diffuse from the top surface into the material and at the same time decay in intensity due to ohmic losses in the material. So long as the eddy currents diffuse, the decay is relatively slow, because of the diffusion inducing new electrical currents in the steel. When the diffusion stops, however, the decay is faster because new currents are no longer induced.

The decaying eddy currents themselves generate a magnetic field in and around the object, which is picked up by a receiver device in the PECT probe, which can be either a magnetic sensor or receiver coils. The signal amplitude can be plotted as a function of time in an A-scan, which is usually presented on a double logarithmic scale. The A-scan has a straight section and a curved section. The point between the straight and curved sections is referred to as the " bending point" and occurs at the onset of the fast decay, meaning when the back has been sensed. The time of the bending point is the "Characteristic time" and is indicative of the steel thickness.

Techshore- Career of NDT

Techshore - Scope of NDT

- Non - destructive testing is a descriptive term used for the examination of materials and components in such a way that allows materials to be examined without changing or destroying their usefulness. NDT or NDE can be used to find, size, and locate surface and subsurface flaws and deflects

- NDT plays a crucial role in everyday life and is necessary to assure safety and reliability.

- NDT is a Quality Assurance management tool which can give impressive results when used correctly. It requires an understanding of the various methods available, their capabilities and limitations, knowledge of the relevant standards and specifications for performing the tests.

Techshore- Career of NDT

Job objective to work with a reputed company as an NDT inspector and to use NDT skills and knowledge their fullest. High lights of Qualification.....Ability to inspect welds, casting, and forgings with the help of the UT instruments. Ability to maintain the equipment and ensure its proper functioning.

Salary Range Up to:-

| Job Title | Salary |

|---|---|

| JetLite NDT Engineer salaries | ₹95,181/month |

| Sievert Group Advanced NDT Engineer salaries | ₹515,886/year |

For more details log on to http://techshore.in/

.png)

No comments:

Post a Comment