Introduction

The tool is sharp shape object of hard material. It is usually made from H. S. Steel. Rather than H.S.S. machine tool is also made from High Carbon Steel, Satellite, Diamond, Ceramics, Abrasive, etc. The main required condition of tool material is hardness. It must be very hard enough to resist cutting forces applied to the work piece. Hot hardness, wear resistance, coefficient of friction, Toughness, Thermal conductivity, & specific heat, are other requirement of tool material. All these properties should be high enough.

Classification of cutting tools

According to number of cutting edge.

1. Single point cutting toolIt is

Examples – shear tools, lathe tools, planer tools, boring tolls etc.

2. Multi point cutting tool

In this more than one single point cutting tools arranged together as a unit. The rate of machining is more & surface finish will be better in this case.

Example- drills, milling cutter, brooches, grinding wheels, abrasive sticks etc.

According to motion

1. Linear motion tools – lathe tools,

2. Linear & rotary motion tools

3. Rotary motion tools – milling cutters, grinding wheels

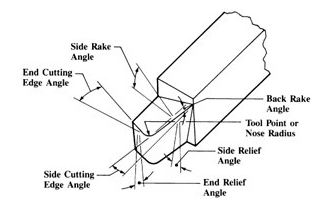

Single point cutting tool geometry

The single point cutting tool mainly consist of cutting part and tool shank called point. The point of cutting tool is covered by cutting face, end flank, side or main flank, & base. The chip slide along the face. The side or main cutting edge ‘ab ’ is formed by intersecting of face & side / main flank The end cutting edge ‘ac ’ is formed by the interconnection of end flank & base. The point ‘a’ which the intersection of side cutting edge and end cutting edge is called nose . Mainly the chip cuts the material by side cutting edge.

Terminology of single point cutting tool

1. Shank – It is

2. Flank – The surface or surface below the area of the cutting edge is called flank of the tool.

3. Face – It is top or

4. Base – It is a bearing surface of the tool when it is situated in tool holder or directly clamped in a tool post.

5. Heel – It is the intersection of the base and

6. Nose – It is the point where

7. Cutting edge – It is the edge on

8. Tool angles-Tool angles have great importance. The tool with accurate angle, reduce breaking of tool, cut metal more efficiently, generate less heat.

9. Noise radius –It

Tool wear

After use of tool forCause of tool

1. Interaction between chip and tool.

2. Cutting forces.

3.

Effect of tool wear

Tool wear changes tool shape, decrease efficiency. Tool wear reduces the dimensional accuracy, loss of surface finish. It increases power consumption during operation.Classification of tool wear

1. Flank wear

2. Craterwear on tool face

3. Chipping

4. Breakage

5. Loss of hardness at high temperature

The width of the wear land (hf) is account as a measure of wear & it is determined by tool maker microscope.

2. Crater

3. Chipping

4. Breakage

5. Loss of hardness at high temperature

1. Flank wear.

It occurs on the flank. It is due to friction between newly machined contact area of flank and workpiece surface . The worn region at flank is called ’wear land’.The width of the wear land (hf) is account as a measure of wear & it is determined by tool maker microscope.

Causes

2. Abrasion by hard particles & inclusions in workpiece.

3. Abrasion by fragment of built up edge.

4. Shearing of micro welds between tool & work.

2. Crater wear

The small cavity or hole is crated on the face of the tool. This small cavity is called ‘crater’ which is formed at some distance from cutting edge.Causes

1. Pressure of chips when it is slide over face of tool.

2. High temperature at tool- chip interface. Some times it creates the melting temperature.

3. Crater wear is more in case of continuous chips of ductile material.

4. Lack of lubrication.

5. Feed is less than 0.15 mm/rev.

6. Low cutting speed.

Best Oil And Gas Institute In Kerala

Best Oil And Gas Institute In Kochi

Best Oil And Gas Institute In Kaloor

Best Oil And Gas Institute In Kollam

Best Oil And Gas Institute In Calicut

Best Oil And Gas Institute In Trivandrum

Best Oil And Gas Institute In Karnataka

Best Oil And Gas Institute In Pathanamthitta

Best Oil And Gas Institute In Mannar

Best Oil And Gas Institute In Kottayam

Best Oil And Gas Institute In Perumbavoor

Best Oil And Gas Institute In Telangana

Best Oil And Gas Institute In Tamilnadu

Best Oil And Gas Institute In Mumbai

Best Oil And Gas Institute In Bahrain

Best Qa/

Best Qa/

Best Qa/

Best Qa/

Best Qa/

Best Qa/

Best Qa/

Best Qa/

Best Qa/

Best Qa/

Best Qa/

Best Qa/

Best Qa/

Best Qa/

Best Qa/

Best Mep Institute In Kerala

Best Mep Institute In Kochi

Best Mep Institute In Kaloor

Best Mep Institute In Kollam

Best Mep Institute In Calicut

Best Mep Institute In Trivandrum

Best Mep Institute In Karnataka

Best Mep Institute In Pathanamthitta

Best Mep Institute In Mannar

Best Mep Institute In Kottayam

Best Mep Institute In Perumbavoor

Best Mep Institute In Telangana

Best Mep Institute In Tamilnadu

Best Mep Institute In Mumbai

Best Mep Institute In Bahrain

Best Instrumentation Institute In Kerala

Best Instrumentation Institute In Kochi

Best Instrumentation Institute In Kaloor

Best Instrumentation Institute In Kollam

Best Instrumentation Institute In Calicut

Best Instrumentation Institute In Trivandrum

Best Instrumentation Institute In Karnataka

Best Instrumentation Institute In Pathanamthitta

Best Instrumentation Institute In Mannar

Best Instrumentation Institute In Kottayam

Best Instrumentation Institute In Perumbavoor

Best Instrumentation Institute In Telangana

Best Instrumentation Institute In Tamilnadu

Best Instrumentation Institute In Mumbai

Best Instrumentation Institute In Bahrain

Best Fire And Safety Institute In Kerala

Best Fire And Safety Institute In Kochi

Best Fire And Safety Institute In Kaloor

Best Fire And Safety Institute In Kollam

Best Fire And Safety Institute In Calicut

Best Fire And Safety Institute In Trivandrum

Best Fire And Safety Institute In Karnataka

Best Fire And Safety Institute In Pathanamthitta

Best Fire And Safety Institute In Mannar

Best Fire And Safety Institute In Kottayam

Best Fire And Safety Institute In Perumbavoor

Best Fire And Safety Institute In Telangana

Best Fire And Safety Institute In Tamilnadu

Best Fire And Safety Institute In Mumbai

Best Fire And Safety Institute In Bahrain

Best Hvac Institute In Kerala

Best Hvac Institute In Kochi

Best Hvac Institute In Kaloor

Best Hvac Institute In Kollam

Best Hvac Institute In Calicut

Best Hvac Institute In Trivandrum

Best Hvac Institute In Karnataka

Best Hvac Institute In Pathanamthitta

Best Hvac Institute In Mannar

Best Hvac Institute In Kottayam

Best Hvac Institute In Perumbavoor

Best Hvac Institute In Telangana

Best Hvac Institute In Tamilnadu

Best Hvac Institute In Mumbai

Best Hvac Institute In Bahrain

Best Logistics Institute In Kerala

Best Logistics Institute In Kochi

Best Logistics Institute In Kaloor

Best Logistics Institute In Kollam

Best Logistics Institute In Calicut

Best Logistics Institute In Trivandrum

Best Logistics Institute In Karnataka

Best Logistics Institute In Pathanamthitta

Best Logistics Institute In Mannar

Best Logistics Institute In Kottayam

Best Logistics Institute In Perumbavoor

Best Logistics Institute In Telangana

Best Logistics Institute In Tamilnadu

Best Logistics Institute In Mumbai

Best Logistics Institute In Bahrain

Best Ndt Institute In Kerala

Best Ndt Institute In Kochi

Best Ndt Institute In Kaloor

Best Ndt Institute In Kollam

Best Ndt Institute In Calicut

Best Ndt Institute In Trivandrum

Best Ndt Institute In Karnataka

Best Ndt Institute In Pathanamthitta

Best Ndt Institute In Mannar

Best Ndt Institute In Kottayam

Best Ndt Institute In Perumbavoor

Best Ndt Institute In Telangana

Best Ndt Institute In Tamilnadu

Best Ndt Institute In Mumbai

Best Ndt Institute In Bahrain

Best Automation Institute In Kerala

Best Automation Institute In Kochi

Best Automation Institute In Kaloor

Best Automation Institute In Kollam

Best Automation Institute In Calicut

Best Automation Institute In Trivandrum

Best Automation Institute In Karnataka

Best Automation Institute In Pathanamthitta

Best Automation Institute In Mannar

Best Automation Institute In Kottayam

Best Automation Institute In Perumbavoor

Best Automation Institute In Telangana

Best Automation Institute In Tamilnadu

Best Automation Institute In Mumbai

Best Automation Institute In Bahrain

Best Concrete Ndt Institute In Kerala

Best Concrete Ndt Institute In Kochi

Best Concrete Ndt Institute In Kaloor

Best Concrete Ndt Institute In Kollam

Best Concrete Ndt Institute In Calicut

Best Concrete Ndt Institute In Trivandrum

Best Concrete Ndt Institute In Karnataka

Best Concrete Ndt Institute In Pathanamthitta

Best Concrete Ndt Institute In Mannar

Best Concrete Ndt Institute In Kottayam

Best Concrete Ndt Institute In Perumbavoor

Best Concrete Ndt Institute In Telangana

Best Concrete Ndt Institute In Tamilnadu

Best Concrete Ndt Institute In Mumbai

Best Concrete Ndt Institute In Bahrain

Best Electrical

Best Electrical

Best Electrical

Best Electrical

Best Electrical

Best Electrical

Best Electrical

Best Electrical

Best Electrical

Best Electrical

Best Electrical

Best Electrical

Best Electrical

Best Electrical

Best Electrical

.png)

No comments:

Post a Comment